|

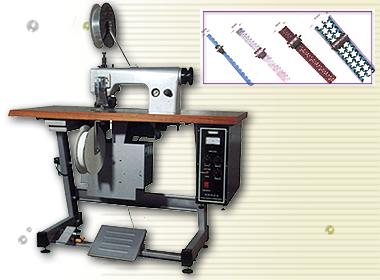

Supersonic

plastic welding machine

|

|

|

Product specification:

|

|

|

•

• • • |

Adopt IC automatic control system, easy

supersonic setting, stable function, adding special overload alarm

light and overload open circuit protection , easy operation, high

safety The components use famous components from America, Japan and Europe, with stable quality, high efficiency, low out-of order, good product, low price. Adopt 4 horizontal screws adjustment, fast and accurate mold adjustment. Professional technicians, complete service net in Taiwan, provide you enough information, design-in and after sale service. |

|

MOLEL

|

OUTPUT

POWER |

FREQUENCY

|

WELING

CAPABILITY |

DIMENSION

|

NET

WEIGHT |

COMPRESSED

AIR |

LINE

SOURCE |

|

MH-W05

|

300W

|

28KHz

|

35Øm/m

|

300x230x100m/m

|

5kg

|

--

|

110V/220VIP

|

|

MH-W15

|

1500W

|

20 KHz

|

170Øm/m

|

580x460x1200m/m |

95kg

|

1/4HP

|

220V/10AIP

|

|

MH-W18

|

1800W

|

15 KHz

|

180Øm/m

|

580x460x1200m/m

|

100kg

|

1/2HP

|

220V/10AIP

|

|

MH-W22

|

2200W

|

15 KHz

|

190Øm/m

|

580x460x1200m/m

|

110kg

|

1/2HP

|

220V/10AIP

|

|

MH-W26

|

2600W

|

15 KHz

|

220Øm/m

|

580x460x1200m/m

|

115kg

|

1/2HP

|

220V/12AIP

|

|

MH-W32

|

3200W

|

15 KHz

|

250Øm/m

|

750x900x2000m/m

|

300kg

|

1HP

|

220V/15A3P

|

|

MH-W42

|

4200W

|

15 KHz

|

300Øm/m

|

750x900x2000m/m

|

300kg

|

1HP

|

220V/20A3P

|